Tidied the corners

so I could do a first fit of the frame

Offered everything up, marked it all out and cut a little more away

I'm leaving these little tabs on top of the pressed deck a little longer so I can tap them down after the frame is welded in to make it all look as factory as possible.

Next thing was to sort out the firewall retaining tab. It's the bit the firewall slots up and into between the fuel tank and the engine bay.

It didn't take much to take out as it was attached to the bottom of the deck panel I removed earlier. It needed bending flat but as a result it ended up with a gentle curve along it's length due to me hitting it with a hammer on an anvil to get rid of the creases. Another half hour spent gently tapping with a hammer to encourage the bend to disappear. Even after half an hour I couldn't get rid of one point where it was bad. In the end I cut the strip at this point which turned out quite handy. In order to weld this to the underside of the new frame I would need to put a new 90 degree bend in and my bending machine can only take something 600mm long so problem solved.

Offered up one of the pieces before trimming it

Then set about welding the two parts to the frame using new plug weld holes

so I could do a first fit of the frame

Offered everything up, marked it all out and cut a little more away

I'm leaving these little tabs on top of the pressed deck a little longer so I can tap them down after the frame is welded in to make it all look as factory as possible.

Next thing was to sort out the firewall retaining tab. It's the bit the firewall slots up and into between the fuel tank and the engine bay.

It didn't take much to take out as it was attached to the bottom of the deck panel I removed earlier. It needed bending flat but as a result it ended up with a gentle curve along it's length due to me hitting it with a hammer on an anvil to get rid of the creases. Another half hour spent gently tapping with a hammer to encourage the bend to disappear. Even after half an hour I couldn't get rid of one point where it was bad. In the end I cut the strip at this point which turned out quite handy. In order to weld this to the underside of the new frame I would need to put a new 90 degree bend in and my bending machine can only take something 600mm long so problem solved.

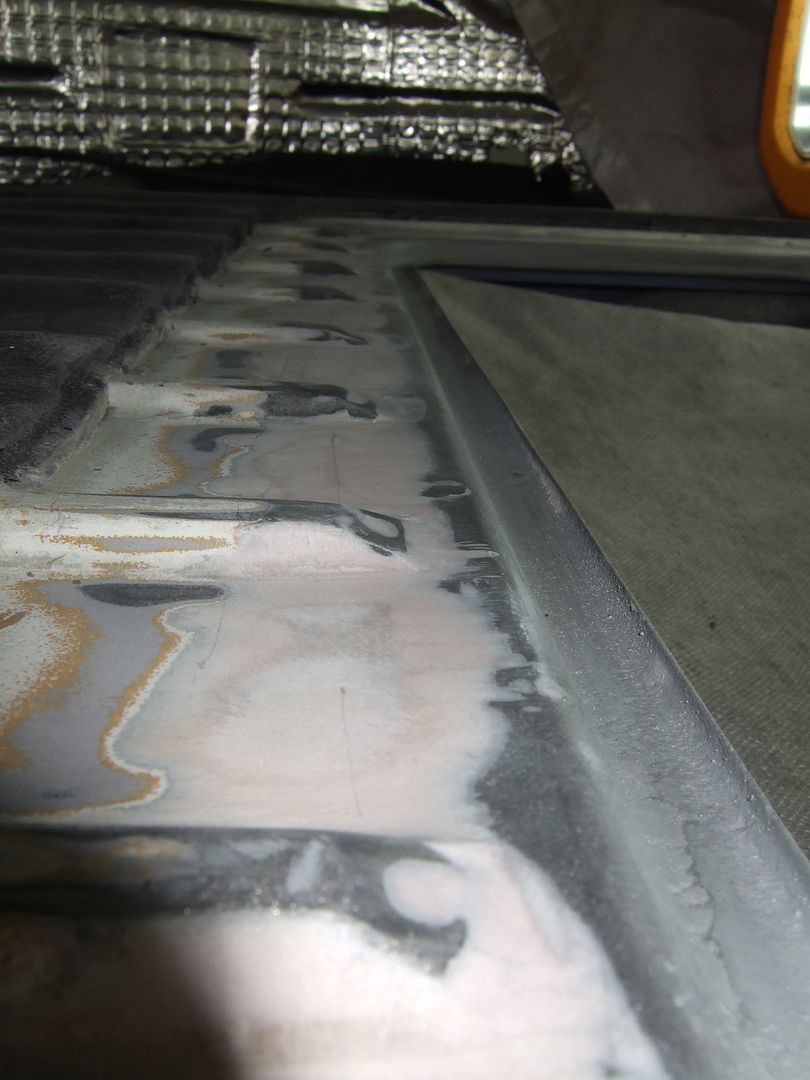

Offered up one of the pieces before trimming it

Then set about welding the two parts to the frame using new plug weld holes