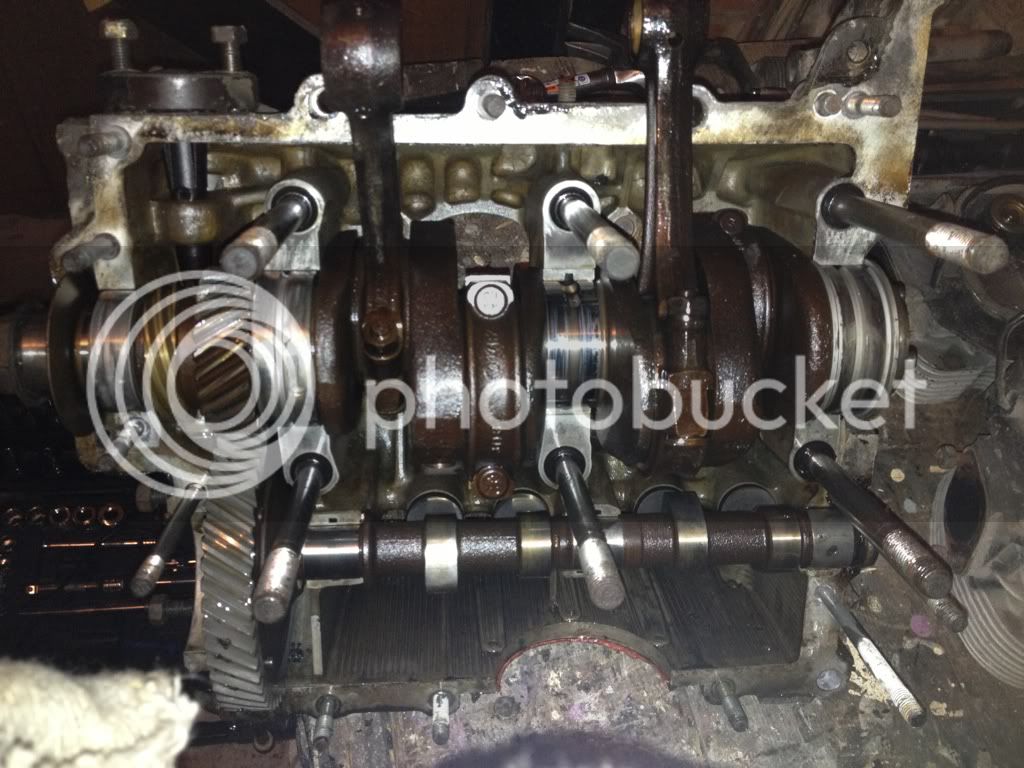

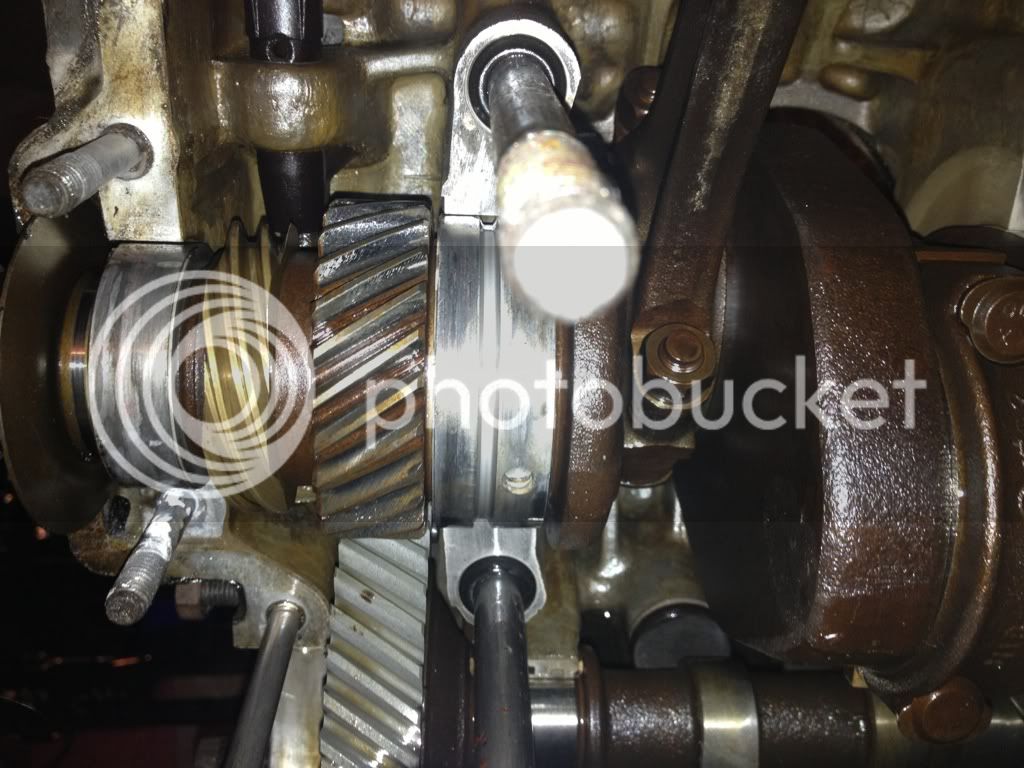

Made a bit of progress today.. Pretty much Stripped down to the short block now, heads seem good with no cracks, but I'll let you guys decide from the pics. I can't see anything though.

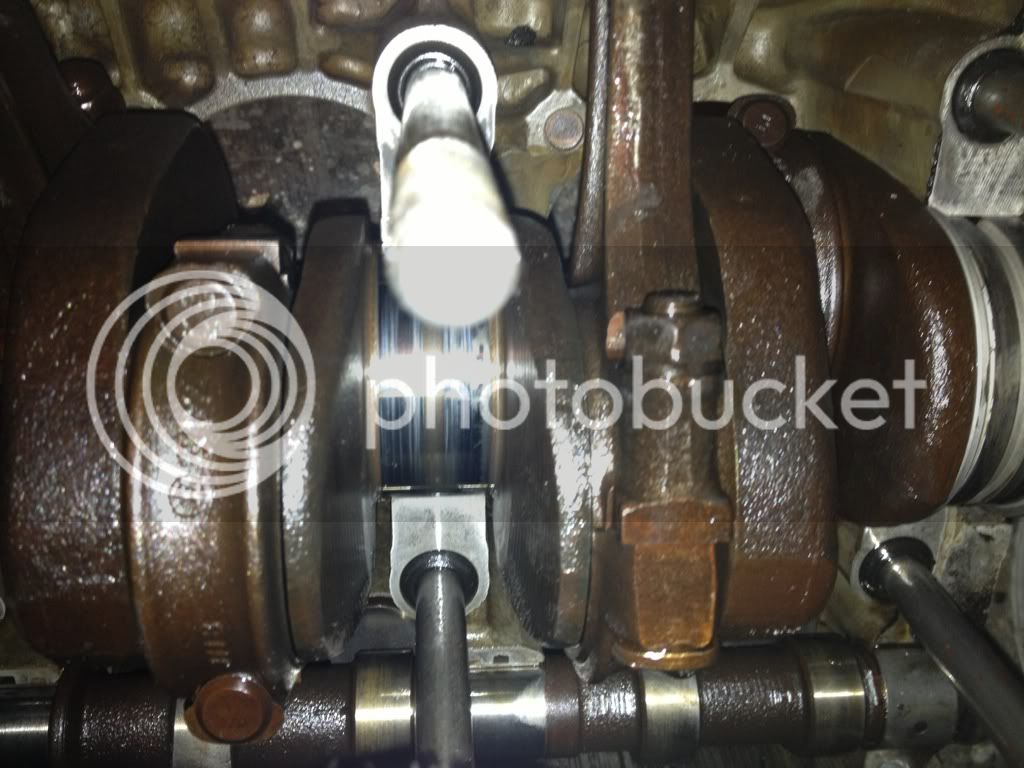

Only thing I did notice is one of the push rods has split, I'm guessing it's been done whilst being moved about as the guy said it had stood for 6 months.

Anyway here's a few piccys this far.

What I couldn't work out is how to get the barrels off, I figured I leave it and consult the Tom Wilson book. The tinware was pretty crap too and had to cut some of it as the screws were jammed in the heads on cyl 1&4. No biggy though.

Only thing I did notice is one of the push rods has split, I'm guessing it's been done whilst being moved about as the guy said it had stood for 6 months.

Anyway here's a few piccys this far.

What I couldn't work out is how to get the barrels off, I figured I leave it and consult the Tom Wilson book. The tinware was pretty crap too and had to cut some of it as the screws were jammed in the heads on cyl 1&4. No biggy though.