atafonso said:

Craig that is a good point i forgot to ask, are you greasing/oiling the shims? They have to go dry while measuring and without the flywheel o'ring. After you happy with the amount of play, you oil the shims, oil the seal and install, oil the o'ring and install, a bit of Loctite on the gland nut and 300ft lbs of torque.

Abel

Yes, I have kept the shims are dry for the measurement taking. :anim_19:

atafonso said:

It looks like you measuring the flywheel flex instead of the endfloat.

I see that your flywheel has been reground, so it's possible that they also reground the area where it meets the crank, that would explain using only 3x0.24mm shims still gives you not enough play.

A solution would be to use two shims. Nothing wrong with that as long as you use the correct thickness and material, the hardened ones.

On aftermarket cranks sometimes we have to use 4 shims as the play is more than stock and impossible to set correctly even with 3x0.40mm which is the thickest shim available.

Abel

I did not ask them to grind the shim-facing area of the flywheel and it doesn't look fresh like the front is, so I assume that is not the problem, although it would explain the issue.

Everything I have read states that x3 shims are required, however, if you are happy to use only x2, then I am too. I guess the only other solution would be to grind the bearing side that meets the shims :?: No idea if this is even possible, but I am certainly not opening the case again, it's been enough work and money to get to this point. :sad0049: :lol: So, I guess the only option is to use x2.

I think if the engine would be happy with x2 as you say, then I'll use x2.

Next time, I'll have to remember to set it just after the case is closed, then if I need to split the case again, it is easier.

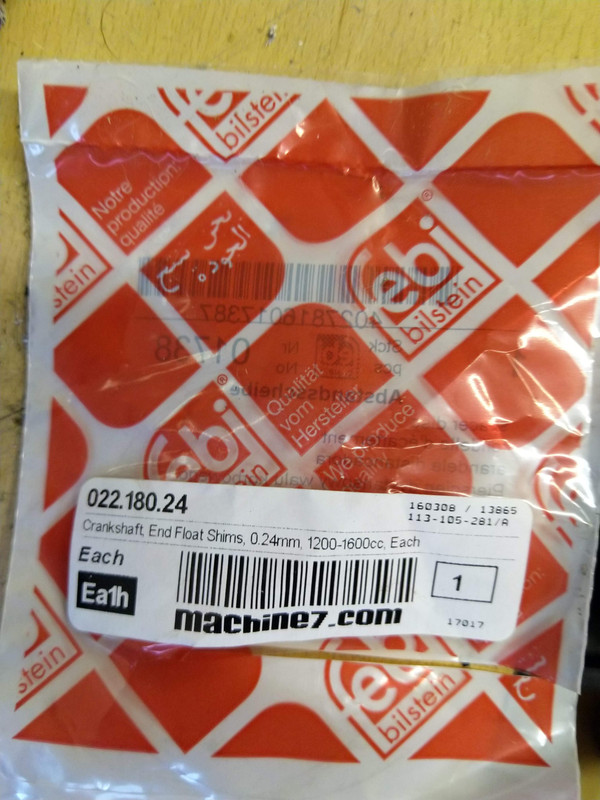

Regarding the material / thickness, they are:

They 'ping' back when bent carefully, so I am hoping they are the ones you are talking about.

atafonso said:

Ps: i don't see the gland nut washer on your pic

I didn't think it would need to be on for the measurement, but I guess I'll do it again to make sure with the spring-washer.

atafonso said:

On the type 1 the felt is inside the gland nut, next to the input shaft bearing bearing

By the way, you are absolutely correct (as always), with this, after looking closely at the flywheel gland nut, it does have an integrated felt seal.