67panel

Well-known member

- Joined

- Jul 30, 2009

- Messages

- 2,797

- Reaction score

- 213

- Location

- malven

- Year of Your Van(s)

- 1968

- Van Type

- panel

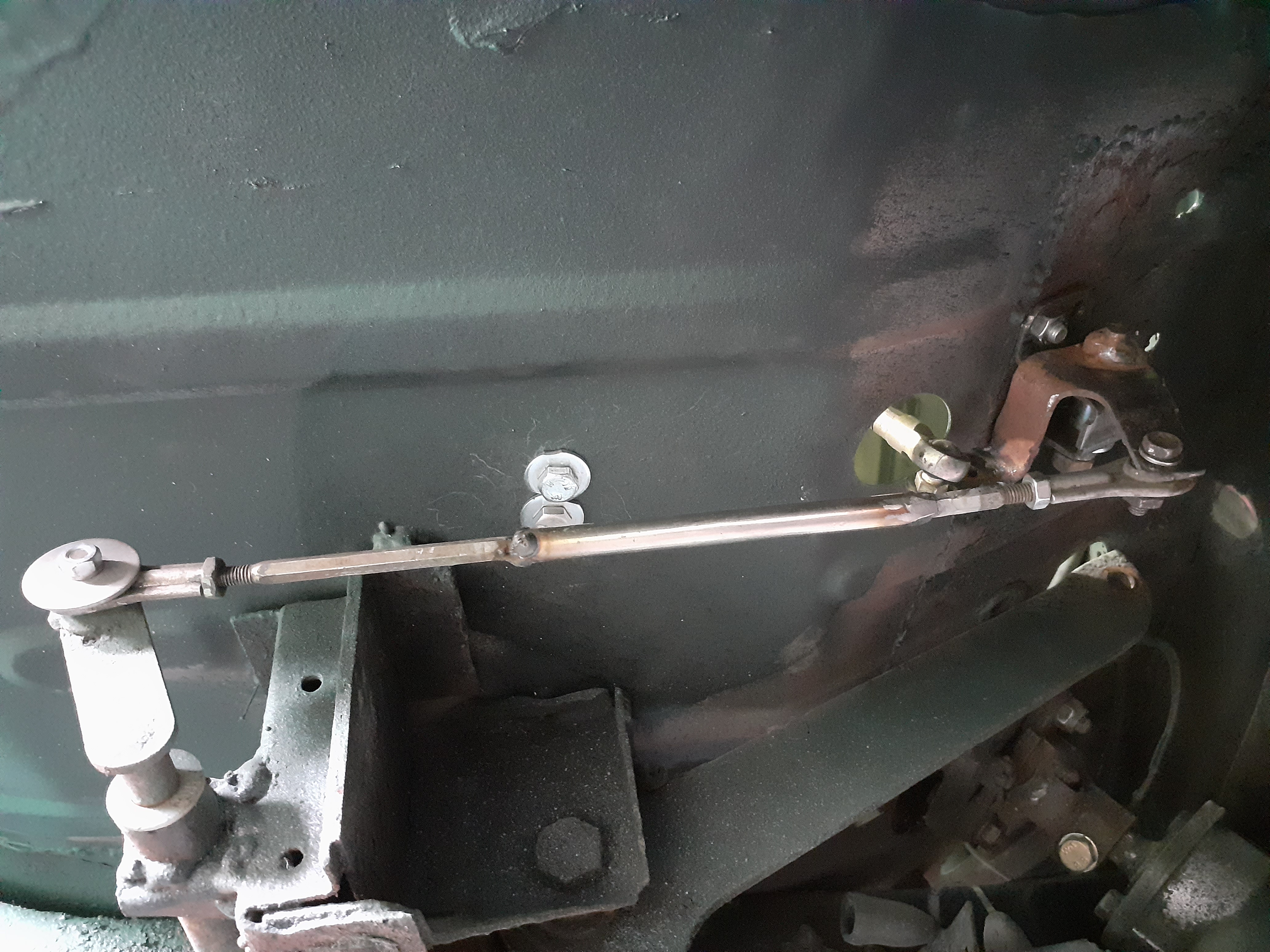

Got side door fitted, took ages to fit all the locks and stuff as had to clean paint and threads from fixings (that darn £50 paint job it had !!) . Took ages picking paint out of crossheads . Waiting for the polishing mop started to clean bits up, spent 1/2 hr just getting paint and 53 years of crud of one door lock. Need to fit a new spring , you know the little one that's always broken. Talking of locks I had to file down shaft of new sliding door handle as it was a bit big for hole in lock mech . Started to polish front panel, ended up doing more wet flatting as it showed up imperfections I thought I had managed to smooth . Think I will flat and polish each section at a time.