- Joined

- Apr 22, 2012

- Messages

- 2,285

- Reaction score

- 321

- Location

- Dorset

- Year of Your Van(s)

- 1971

- Van Type

- Dormobile

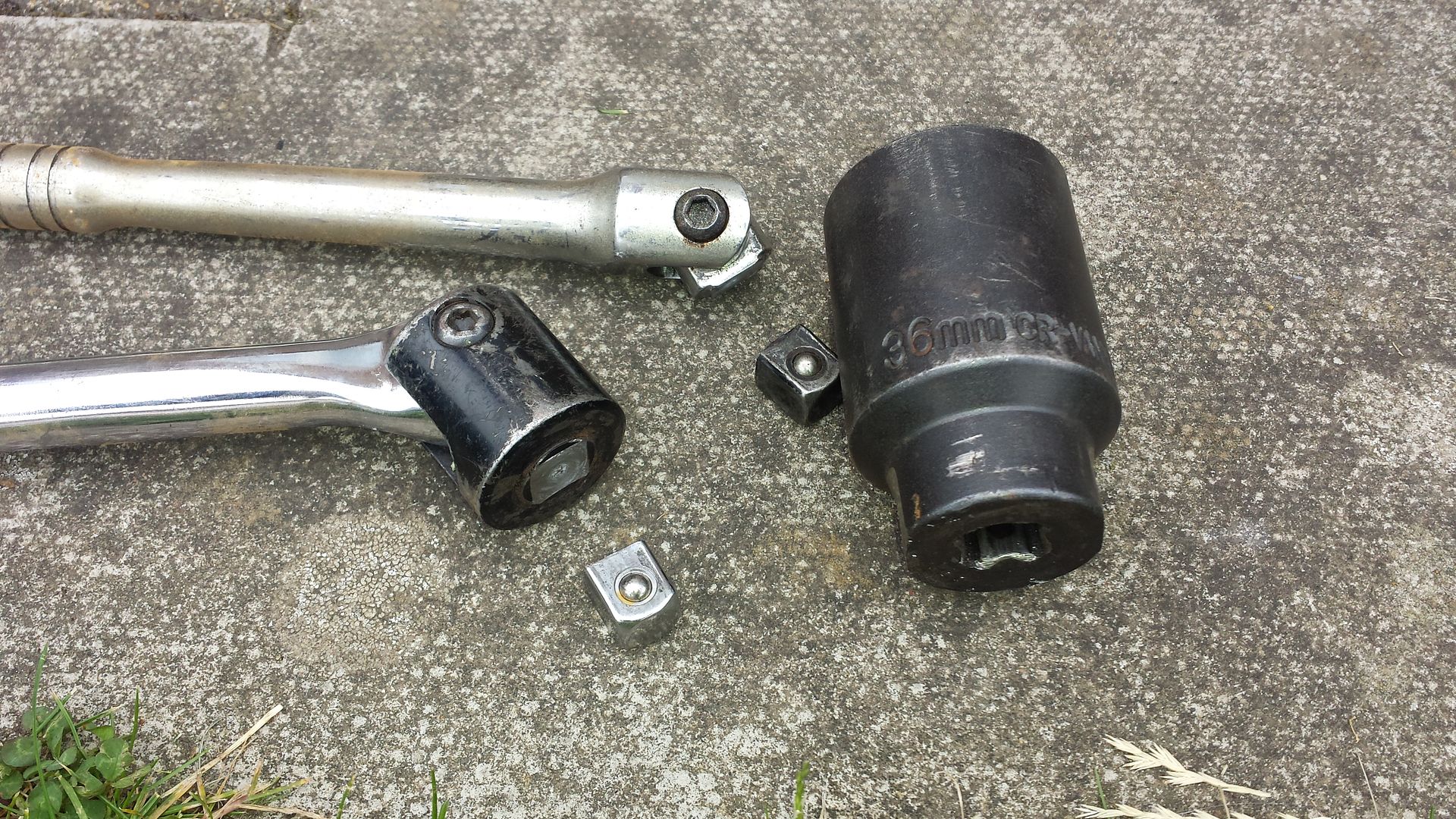

Damn!!!!!!!!!!! :shock: :shock:

I guess the bar has had it now , why don't you get it welded to the socket, then you will always have it handy. :lol:

Great progress though, and a job well done!!

J & P

I guess the bar has had it now , why don't you get it welded to the socket, then you will always have it handy. :lol:

Great progress though, and a job well done!!

J & P