cunning plan said:Very nice dude.arty0021:

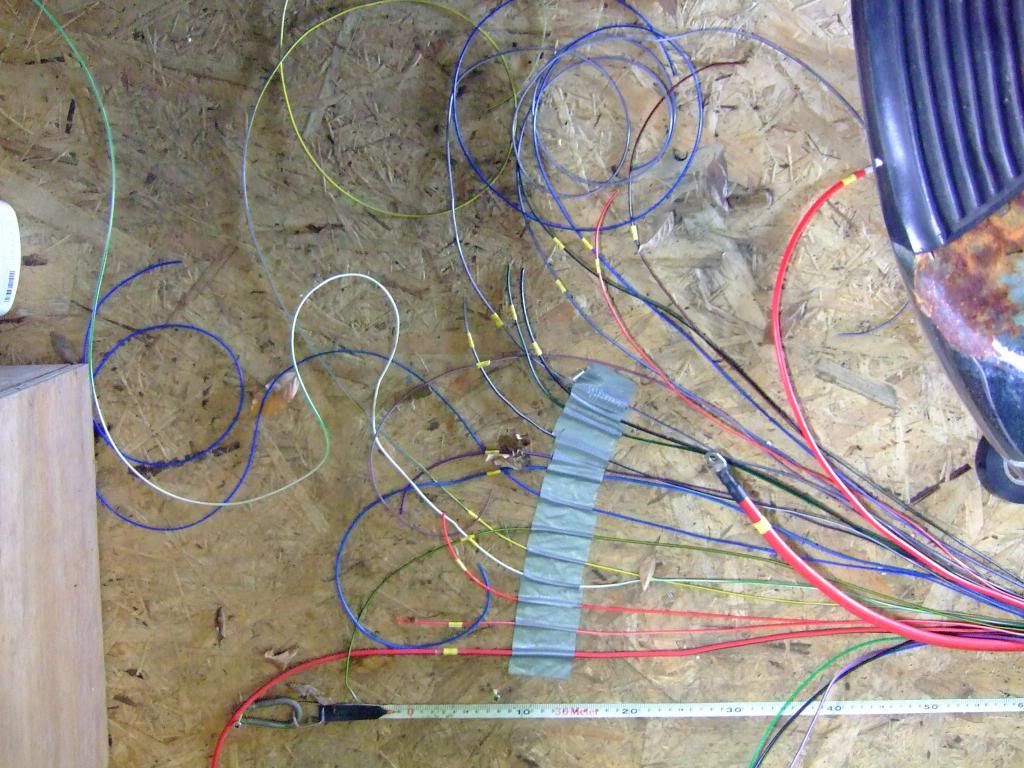

After I have done the headlining on my bus and fitted the windows I will be getting on with the wiring loom. I hope it turns out half as tidy as yours!

Thanks bud. I haven't forgotten I said I'd help you out when it comes to doing yours. Just a thought though, if you're going to do your headlining you might want to replace your internal lighting loom BEFORE you do. It's not complicated but it is a bit fiddly, next to impossible with a headliner in place. I'm replacing mine (of course!) and given that most new LED lighting is fairly low power you will not need to use heavier cable than VW originally used.